Alaska Meat Care Expert Playbook: Field Dressing Tips and Secrets

by Larry Bartlett

When I was a little squirt I relied on my dad to show me how to deal with wild game once taken down. Unfortunately, he was a pretty inexperienced hunter so my only lesson on field dressing was “gut the buck—get it to the truck!” From that point I recall whole legs of deer stacked like cordwood in the chest freezer for so many years they became an unsightly collection of desiccated mummy parts.

Today I am an authority on meat care, likely thanks to my father’s lack of it. Over 25 years of meat care lessons have allowed me to consolidate a playbook of secrets and field dressing tips that every Alaska meat handler should review. Here are my top 5 meat care secrets.

Secret #1 Science doesn’t care what you think is true

Air temperature decides the wild meat preservation window. Meat spoilage is a real threat when storage temperatures are above 55F° because this temperature zone makes bacteria and auto-decay enzymes more active. When deep tissue temperatures reach 60F°, autolysis (bone sour) and fat rancidity become imminent threats.

After muscle groups are removed from the carcass, the internal temperature of wild meat cools down at a predictable rate, which is controlled by the air temperature and relative humidity during storage.

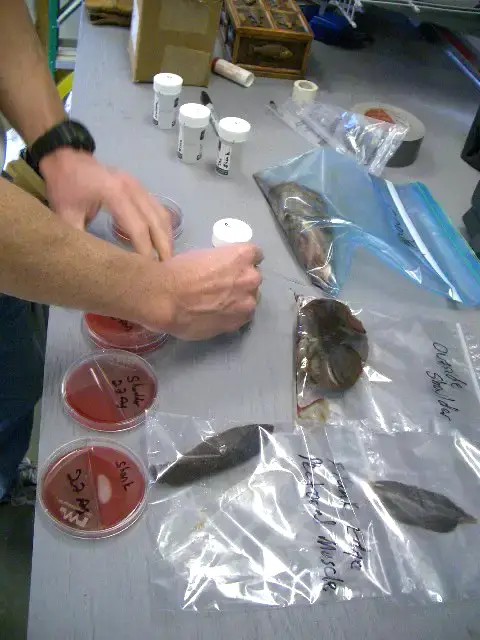

Spoilage threats on the surface of meat are unstable (lag phase) during the first 24-36 hours while meat core temperatures dive from 100F° (time of death) to a resting temperature near the average daily storage temperature. This thermal transition bottoms out during equilibrium and it marks the moment when the meat finds a resting balance with the storage environment. Therefore, surface trimming needs to be thoroughly fleshed out by Day 2 of meat care to establish a clean and fresh cache of edible meat that will be transported out of the field and preserved along the way. This is field dressing tip number one.

Secret #2 Citric acid does NOT promote crust development on meat surfaces

Citric acid mist has one purpose for meat preservation—to temporarily shock or retard spoilage threats like bacteria and blow flies. Surface crust develops on the meat, helping preserve and protect the bulk of fresh meat below the surface. The storage environment needs two things for surface crust to develop: wind and a low relative humidity (RH <78%). Relative humidity controls the evaporation rate on meat surfaces and wind helps it to dry. Meat surfaces often sweat with RH>85%. Citric acid won’t help at all because it’s a liquid mist that adds moisture to sweaty meat.

Secret #3 I rarely use citric acid

Blowfly activity is controlled by the air temperature around the meat. I use 50F° as a rule of thumb to mitigate blow flies and spoilage threats. So, the air temperature at the kill site decides whether I spray citric acid on meat surfaces as it is removed from the carcass. If it’s cooler than 50F°, there is no need to use citric acid while field dressing until after equilibrium on the post-harvest timeline (30-48 hours post- harvest).

After equilibrium surface threats have a stable and friendly environment to thrive, but spoilage activity is controlled by surface moisture and storage temperature. When it’s warmer than 50F° meat generally stays inside game bags. A field dressing tip to keep in mind is any exposed meat should be sprayed once with an acid mist and allowed to dry. My studies showed the best results with a max of two applications one day apart. Application day, skip a day, application day, discontinue. I would only apply the 2nd mist if daily temps were at or near 60F°. Too much citric acid risks moist, acid-burn surfaces that extend deeper and may appear gray and unpleasant.

Secret #4 Practical citric acid mixture

The goal when mixing citric acid powder with water is to create an acid solution. What is “acid” on the pH scale? Clean water and blood baseline is pH 7. Most bacteria need pH5+ environments. If I have a 6-oz spray bottle, I’ll add citric acid powder by the teaspoon until it tastes tart (acid) on the tongue. If you happen to have a small pH test kit (who doesn’t?) the mixture would likely litmus around pH 2. Once shaken and dissolved, a light mist evenly applied will deter blow flies and surface bacteria. Two applications one day apart is all you need. Most bacteria and surface threats have been identified through sensory checks and trimming by day 4 and 5 post harvest, so it’s rare to need a third application from my experience.

Secret #5 Meat Tarps are useful tools

Here’s another field dressing tip, use a tarp. The primary goal with using a tarp is to shield game meat from threats like sunlight and precipitation. I take it a step further and suggest hunters need a small handful of sizes for different purposes.

- A small bivy tent footprint can serve as a place to stage kill site tools, used as a meat trimming station and on the raft to cover meat.

- An 8’ X 10’ tarp has many uses in camp. I prefer sil-nylon over the cheap tarpaulins from the hardware store.

- Custom meat tarps have all the anchor features needed for meat cache scenarios, on and off the raft.

- It’s common for me to pack up to 5 tarps of various sizes to cover all imaginable scenarios.

I hope these field dressing tips and secrets improve your meat quality and experience. For more tips read this meat care post.

Check out relevant YouTube videos by Larry for more tips and information.

If you like our videos, products or brand, please follow our YouTube channel and leave a comment.